Tel: 01474 876800 • Client Portal

- Who We Are

- What We Do

- Build

- Carpentry

- Building Works

- Commercial Flooring

- Commercial Glazing

- Commercial Locksmith

- Commercial Painting & Decorating

- Commercial Plastering

- Commercial Plumbing

- Commercial Refurbishment

- Commercial Roofing

- Design & Construction

- Electrical Installation

- Hard & Soft Landscaping

- Mechanical & Electrical

- Office Builders

- Office Fit Outs

- Office Heating

- Office Partitioning

- Office Relocation

- Site Management

- Maintain

- 24 Hour Helpdesk

- Access Control

- Air Conditioner Repair

- Air Conditioning Servicing

- Commercial Boiler Servicing

- Commercial Electricians

- Commercial Ground Maintenance

- Commercial Pest Control

- Commercial Property Maintenance

- Drain Unblocking

- Emergency Callouts

- Emergency Light Testing

- Facilities Management

- Fire Alarm Testing

- Fire Extinguisher Testing

- Fire Sprinkler Testing

- Fixed Wire Testing

- Handyman Service

- Lift Servicing

- Office Health & Safety

- PAT Testing

- Planned Preventative Maintenance

- Reactive Maintenance

- Roof Maintenance

- TMV Maintenance

- Water Hygiene

- Clean

- Build

- How We Do It

- Why Use Us

- Contact

What is PAT Testing?

Keeping people safe from electronic dangers is critical, whether that’s an employee, tenant or pupil, and PAT testing can help with keeping people safe from electrical dangers.

But what exactly is PAT testing?

Portable Appliance Testing, commonly known as PAT testing, is an essential safety check for electrical appliances.

It helps to ensure that devices used in homes, offices, and workplaces are safe to operate.

Understanding what PAT testing involves and why it is necessary can help you maintain a safe environment and comply with safety standards.

This article will cover what PAT testing is, why it’s important, and who needs it.

We’ll also discuss how often PAT testing should be done, whether it’s a legal requirement, and whether you can perform it yourself.

Table of Contents

What is PAT Testing?

PAT testing is the process of checking electrical appliances to ensure they are safe to use.

This involves both visual inspections and electrical tests.

The aim is to detect any potential hazards, such as faulty wiring, exposed parts, or other defects that could lead to electric shock or fire.

PAT testing is primarily used for portable appliances, which include any electrical device that can be moved and plugged into a power outlet.

These appliances can range from office equipment like computers and printers to household items such as kettles, microwaves, and toasters.

The process of PAT testing ensures that all portable electrical appliances meet safety standards. It helps to prevent accidents, protects property, and reduces the risk of injury to users.

Why is PAT Testing Needed?

PAT testing is needed to maintain the safety of electrical appliances.

Ensuring Safety

PAT testing is needed to ensure that electrical appliances are safe to use.

Faulty equipment can lead to electric shocks, fires, or even explosions.

By regularly testing appliances, you can identify and fix any potential issues, reducing the risk of accidents.

Preventing Hazards

Electrical appliances, especially those used frequently, can wear out over time.

Frayed cords, exposed wires, and damaged plugs can create hazards.

PAT testing helps detect these problems early, preventing serious incidents in homes, offices, and workplaces.

Legal Compliance

For businesses and landlords, PAT testing is essential to meet health and safety regulations.

Employers and property owners are legally required to provide safe equipment.

Regular testing demonstrates compliance and protects against legal repercussions if an accident occurs.

Protecting Employees and Tenants

PAT testing ensures that appliances used by employees and tenants are functioning properly.

This helps create a safer working and living environment, building trust and reducing the chances of accidents.

Reducing Costs

While PAT testing involves a small cost, it can save money in the long run.

By identifying and fixing faults early, you can avoid expensive repairs or replacements and prevent potential liability for accidents.

What Happens During PAT Testing?

For a full PAT test, there are many different steps to ensure a thorough inspection.

Visual Inspection

The first step in PAT testing is a visual inspection.

The technician examines the appliance for any obvious signs of damage.

This includes checking for frayed cables, cracked plugs, and any visible wear and tear.

The plug’s fuse is also inspected to ensure it is the correct type and securely in place.

These visual checks help identify problems that can cause electrical hazards.

Earth Continuity Test

For appliances with a metal casing, an earth continuity test is performed.

This test ensures that the earth wire is properly connected.

If a fault occurs, the earth wire helps safely discharge any excess electricity, reducing the risk of electric shock.

Insulation Resistance Test

The insulation resistance test checks the appliance’s wiring insulation.

Good insulation prevents current from leaking out, which could cause electric shock or fire.

The tester sends a voltage through the wires to ensure the insulation is intact and provides adequate protection.

Polarity Check

A polarity check ensures that the live, neutral, and earth wires are correctly connected.

Incorrect wiring can lead to dangerous malfunctions.

This test confirms that the appliance’s internal wiring is safe and functional.

Leakage Test

The leakage test measures any current leaking from the appliance.

Leakage current can pose a risk of electric shock if the appliance is faulty.

The test ensures that any current leakage is within safe limits, indicating that the appliance is safe to use.

Labelling and Documentation

Once the tests are complete, the appliance is labelled with a PAT testing sticker.

This label shows the date of the test and when the next test is due.

The technician also provides documentation outlining the results of the test, which is useful for record-keeping and compliance with safety regulations.

Who Needs to Have PAT Testing?

PAT testing is required for anyone responsible for the safety of electrical appliances.

This includes businesses, landlords, and organisations where electrical devices are regularly used by staff, tenants, or the public.

Businesses

Employers need to ensure that all electrical appliances used by their staff are safe.

This applies to all industries, from offices and retail shops to construction sites and factories.

Any business that uses portable appliances must conduct regular PAT testing to reduce the risk of accidents.

Landlords

Landlords who provide electrical appliances in rented properties are responsible for ensuring those appliances are safe.

Regular PAT testing helps landlords comply with safety regulations and protects tenants from faulty equipment.

Public Sector Organisations

Schools, hospitals, libraries, and other public buildings often use a wide range of electrical appliances.

PAT testing helps ensure the safety of staff, students, patients, and visitors in these environments.

Event Organisers

PAT testing is also important for events where electrical equipment is used, such as concerts, fairs, and conferences.

Temporary equipment set up for these events should be tested to ensure safety.

How Often is PAT Testing Done?

How often PAT testing is done depends on the type of appliance and the environment in which it’s used.

Different appliances pose different levels of risk, and testing frequency should be based on the risk level.

- High-risk appliances (e.g., power tools) in demanding environments should be tested more frequently.

- Low-risk appliances (e.g., office computers) in safer environments may only need testing every few years.

In general, appliances in high-traffic areas or heavy-use environments should be tested more often.

A risk assessment can help determine the appropriate frequency for PAT testing in your specific situation.

For businesses, it is common to have PAT testing done annually or biannually, but this varies depending on the industry.

Landlords often conduct PAT testing annually or when new tenants move in to ensure all appliances are safe.

Is PAT Testing a Legal Requirement?

In the UK, PAT testing is not a legal requirement by itself, but it is strongly recommended to comply with health and safety regulations.

Employers, landlords, and business owners have a legal obligation to ensure that the electrical equipment they provide is safe.

Several pieces of legislation outline the responsibility to maintain safe electrical appliances, such as:

While none of these laws explicitly state that PAT testing is mandatory, they require employers and landlords to ensure their equipment is safe.

PAT testing is the most reliable way to fulfil these legal obligations.

Regular testing and maintenance help demonstrate that you’ve taken reasonable steps to ensure safety and reduce the risk of accidents.

Can I do PAT Testing Myself?

Yes, you can do PAT testing yourself, but only under certain conditions.

If you have the right knowledge, skills, and equipment, you can carry out basic PAT testing, especially for low-risk appliances like office equipment.

However, for high-risk appliances or more complex testing, it is recommended to hire a qualified technician.

PAT testing requires specialised tools and a thorough understanding of electrical safety. Without proper training, it’s easy to miss faults that could pose a danger.

To carry out PAT testing yourself, you will need:

Training

While formal certification is not required, you must have a clear understanding of electrical safety and PAT testing procedures.

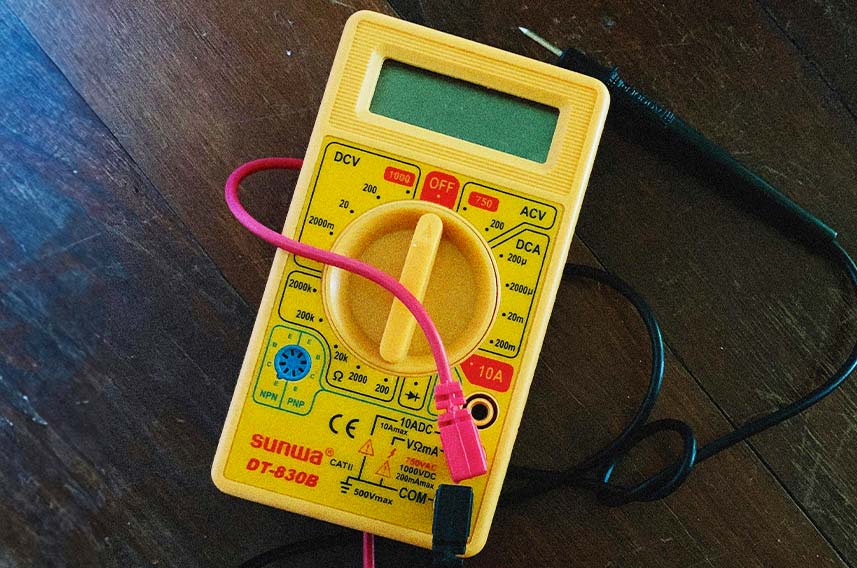

Equipment

A PAT testing device is necessary to perform electrical tests on appliances.

For businesses or landlords with many appliances, hiring a professional ensures that testing is done correctly.

Trained technicians can provide documentation, proper labelling, and ensure compliance with safety standards.

Conclusion

Hopefully this article answered your question of exactly what is PAT testing.

PAT testing is a crucial safety measure that ensures electrical appliances are safe to use.

Whether you’re a business owner, landlord, or event organiser, regular PAT testing helps reduce the risk of electrical accidents and ensures compliance with safety regulations.

While PAT testing is not a strict legal requirement, it’s highly recommended for meeting health and safety obligations.

Knowing when to test, who should be tested, and how often is important for maintaining a safe environment.

By conducting PAT testing regularly, you can identify potential problems early, avoid dangerous situations, and ensure that your electrical appliances are in good working order.

Whether you choose to do it yourself or hire a professional, the goal remains the same: keeping everyone safe from electrical hazards.

For more information on PAT testing, or to organise a PAT test on your equipment, then get in contact with us at ECMS.

Request a Callback

Recent Posts

- 10 Common Saniflo Toilet Troubleshooting Solutions 01th Jul 2025

- Importance of Personal Hygiene at Work 01th Jun 2025

- How to Clean a Toilet Brush 01th May 2025

- How to Clean Painted Walls 01th Apr 2025

- How to Get Oil Stains Out of Carpet 01th Mar 2025

- How to Clean a Fridge and Remove Bad Smells 01th Feb 2025

- How to Get Coffee Stains Out of a Carpet 01th Jan 2025

- How to Clean Gutters Correctly 01th Dec 2024

- What is PAT Testing? 01th Nov 2024

- How to Clean an Oven 01th Oct 2024